Our sand-lime brick production

The company learned a whole new generation of aac blocks manufacturing process, through multi-level technological innovation, formed a Dongyue sand-lime brick manufacturing process. We have obtained ISO9001 international quality management system certification, CE certification, the most credible international certification and assessment of the French BV group and the German Rhine TUV group

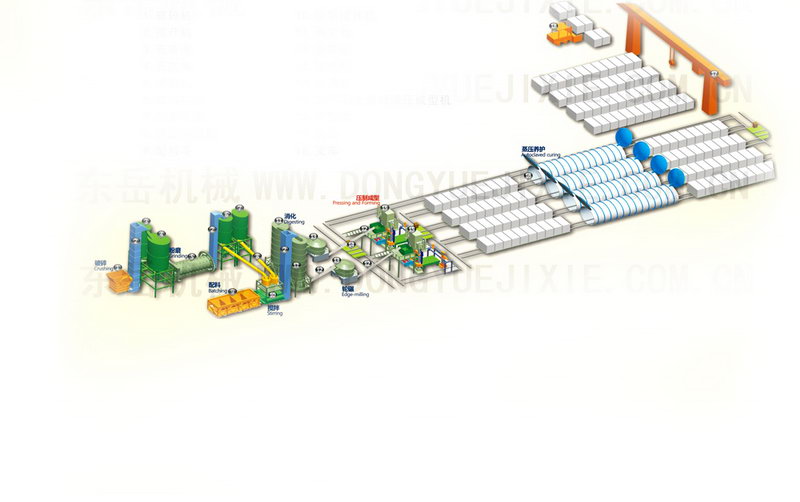

production process flow(3D View)

Our host machine

Batching &Mixing

The raw materials are unloaded to the distributing bin, transported to the electrical measuring device through the conveyer and finally feed into the mixer in certain proportion. Then the water is fed into the raw material. The mixed materials will be sent to the slaking silo and transported to the secondary mixer for humidifying stirring. Then the materials are conveyed to the hopper for pressing.

Molding process.

The pressing is an important part for the entire production process, which is the key and lays a foundation for the finished products to meet national industry standards.Electric automatic feeding device makes the prepared curing blocks formed one time in the pressing, and then put the mould removed bricks on steam cart by the automatic palletizers.

Curing and storage

The steaming trolley with stacked blocks enters into the pre-curing area and is dragged by the tractor into the autoclave for steaming. After the steaming process, the trolley is pulled out and carried to the finished products warehouse by forklift.

Production display