Aerated block machine and Aerated block production line manufacture from Donyue machinery group.Our company is a high-tech enterprise in ShanDon Province with technology research and development center, and has been applied for the establishment of the National Technology Enterprise Center and postdoctoral workstation;The annual output of more than 5,000 units of block machine , aerated block and panel production line of more than 500. Annual capacity of 10-40 million cubic meters of Aerated block machine and Aerated block production line.

Autoclaved Aerated Concrete Block Production Line

.

Project Capability Assessment

Our

Company is one of the three biggest autoclaved aerated concrete block making

equipment manufacturers in China. Also, it is an international well-known maker

who is specified in offering wall materials production equipment. In the head

quarter, we have a technical research team, which is led by the famous professor

from Chinese Academy of Engineering. This research team has the communication

channel with the Association for Manufacturing Technology, and other related

institutions. By uniting the domestic and overseas technologies, it has

developed the autoclaved aerated concrete block production line. The production

line is CE certified in 2008. Later in 2010, it is honored as the Chinese

reputed trademark. Especially in 2010, it was certified by the international

most authoritative institutions, such as the BUREAU VERITAS and German TüV. By

right of the exquisite technology and meticulous service, the production line

enjoys tremendous popularity in the world. It sells well in Russia, Indonesian,

Vietnam, India, and so forth.

Ⅰ.

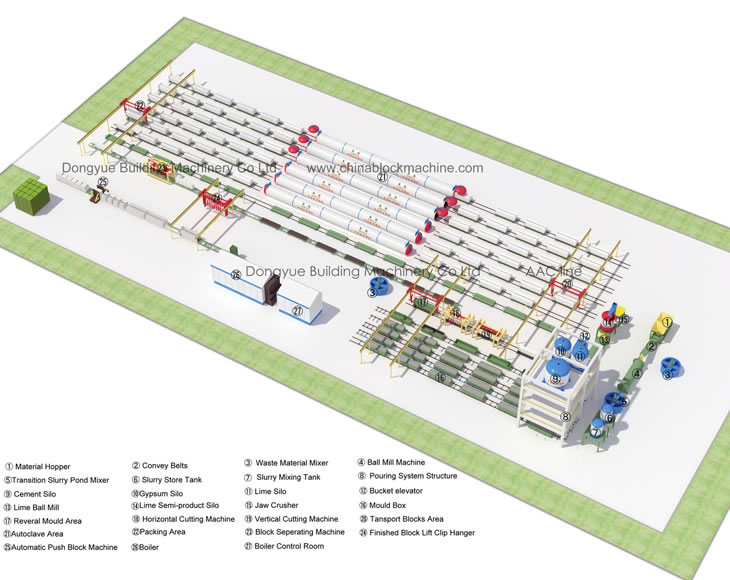

Introduction of Autoclaved Aerated Concrete Block Production Line

In

accordance with different main materials, we can design the production line,

which is capable for annually producing 100,000 to 400,000m3 coal ash or sand

autoclaved aerated concrete blocks. Here below is the production process of

autoclaved aerated concrete block production line.

Aerated block

production line process

1、 Raw material

storage

Fly ash or sand,cement,lime,gypsum,aluminum paste

should be stored separately in the materials stock yard, transport them to

workshop when use them.

2、 Raw material dealing

process

Put the fly ash or sand into the ball mill to mill via

the conveyor belt, after milling, put the slurry into the slurry storage tank by

slurry pump.

3、Batching, mixing and pouring

process

The lime, cement will convey by conveyor to the dry

powder measure scale to scale separately. The slurry convey by slurry pump then

to the automatic scale;the power and slurry put into the mixer,pouring into the

mould.

4、Curing,cutting

After slurry pouring into

the mould, put the mould box into the curing room with 50~70℃. After 2-3 hours

curing,the blocks become solid,using reversal crane carry the mould and block to

demould on cutting cart. The cutting cart will take the block to level cutting

machine,vertical cutting ,two sides cutting,and remove the top waste

material.

5、 Autoclaved and finished product

Finished cutting using semi-product crane carry to the front of autoclave

grouped,hoisting machine or dragger will drag steam trolley into autoclave to

steam,after steamed 8 or 10 hours ,driven out by hoisting machine or dragger

again,the finished block after separating,packing, transport the products by

forklift to piled yard.

| Process Flow Diagram | |

| |

| Ⅲ. Autoclaved Aerated Concrete Block Factory Designed by Our Company | |

| |

| Ⅳ. Autoclaved Aerated Concrete Block Production Line | |

| Autoclaved Aerated Concrete Block Sample | Vietnam Factory |

|  |

| Indonesia Factory | Sample Diagram |

|  |